FDA 21 CFR Part 11 and GxP is the set of regulations issued by the U.S. Food and Drug Administration (FDA) that defines the criteria under which electronic records and electronic signatures are considered trustworthy, reliable, and equivalent to paper records and handwritten signatures. It applies to all industries regulated by the FDA, including pharmaceuticals, biotechnology, medical devices, and food, wherever GxP guidelines are in effect.

What is FDA 21 CFR Part 11 and GxP?

To fully understand 21 CFR Part 11, one must first grasp the concept of GxP. GxP is a collection of quality guidelines and regulations designed to ensure that products are safe, meet their intended use, and adhere to quality processes. The “x” stands for various fields, such as Good Clinical Practice (GCP), Good Laboratory Practice (GLP), and Good Manufacturing Practice (GMP). These guidelines mandate rigorous documentation and record-keeping to provide an auditable trail of every action and decision throughout a product’s lifecycle.

As the industry shifted from paper-based systems to digital ones, a regulatory gap emerged. The FDA needed to assure that electronic records were just as dependable as their paper counterparts. This led to the creation of 21 CFR Part 11 in 1997. The rule doesn’t stand alone; it works in conjunction with existing GxP rules. If a GxP regulation requires a record, signature, or documentation, Part 11 provides the framework for implementing that requirement electronically.

The regulation is broadly divided into two main areas: controls for electronic records and controls for electronic signatures. For electronic records, it mandates features like audit trails, system validation, and secure, timestamped recordkeeping. For electronic signatures, it requires that they be uniquely linked to an individual, include rigorous identity verification, and cannot be reassigned to anyone else.

Why is FDA 21 CFR Part 11 and GxP Important?

Compliance with 21 CFR Part 11 and the underlying GxP principles is not optional; it is a legal mandate for doing business in the life sciences sector. The importance, however, extends far beyond simply avoiding regulatory action. Robust compliance is a cornerstone of product quality, patient safety, and operational excellence.

- Regulatory Mandate and Market Access: Non-compliance can lead to severe consequences, including FDA warning letters, clinical holds, product recalls, seizure of products, injunctions, and even criminal prosecution. Adherence is the key to getting products approved and maintaining them on the market.

- Ensures Data Integrity and Accuracy: At its core, Part 11 is about data integrity, the ALCOA+ principles (Attributable, Legible, Contemporaneous, Original, and Accurate, plus Complete, Consistent, Enduring, and Available). Compliant systems are designed to prevent data errors, loss, and tampering, ensuring that decisions are based on complete and accurate information.

- Protects Patient Safety: Faulty data from non-compliant systems can lead to the approval of an unsafe or ineffective drug, device, or therapy. By ensuring data reliability, Part 11 and GxP act as a critical safeguard for public health.

- Enhances Operational Efficiency: While achieving compliance requires investment, a well-implemented Part 11/GxP system streamlines processes. It reduces the inefficiencies of paper-based systems, automates workflows, and enables faster access to accurate data for decision-making.

- Facilitates Successful Audits and Inspections: Both internal and external audits are a routine part of a regulated company’s life. A demonstrably Part 11-compliant system provides inspectors with a clear, easily auditable trail, leading to smoother, faster, and more successful inspections.

- Builds Trust with Stakeholders: Compliance demonstrates a company’s commitment to quality and regulatory rigor. This builds trust with regulators, investors, partners, and, ultimately, the patients who use the products.

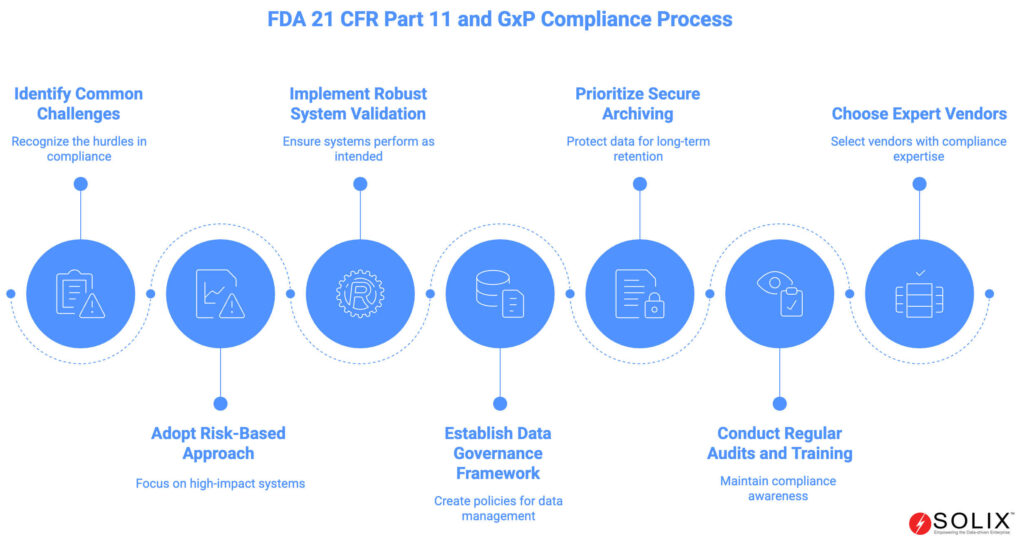

Key Challenges and Best Practices of FDA 21 CFR Part 11 and GxP Compliance for Businesses

Implementing and maintaining 21 CFR Part 11 compliance within a GxP framework presents several significant challenges. Understanding these hurdles and adopting industry best practices is crucial for long-term success.

Common Challenges:

- System Validation Complexity: Proving that a computer system consistently does what it is supposed to do is a foundational requirement. Many organizations struggle with the scope, documentation, and execution of a thorough validation protocol (IQ/OQ/PQ).

- Managing Audit Trails: Ensuring that systems generate secure, computer-generated, timestamped audit trails that track operator actions is one thing. Effectively managing, reviewing, and archiving these vast volumes of data for the required retention periods is another major challenge.

- Legacy System Integration: Many organizations operate with a mix of modern and legacy systems. Bringing these older systems, which were not designed with Part 11 in mind, into compliance can be technically difficult and costly.

- Ensuring Data Security and Access Controls: Defining and managing user roles with strict access privileges to ensure individuals cannot alter or delete records they shouldn’t is a continuous administrative and technical task. Preventing unauthorized access is paramount.

- Electronic Signature Non-Binding: Implementing electronic signatures that are legally binding, uniquely identifiable to a person, and include a clear meaning (e.g., approval, review) requires careful process and technical design.

- Changing Organizational Culture: Compliance is not just an IT issue. It requires a cultural shift where every employee, from the lab technician to the C-suite, understands and adheres to data integrity principles in their daily work.

Essential Best Practices:

- Adopt a Risk-Based Approach: Focus your compliance efforts on systems and data that have the highest impact on product quality and patient safety. Not every system requires the same level of control.

- Implement Robust System Validation: Never take a system’s performance for granted. Develop a comprehensive validation plan that includes Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) to prove the system is fit for its intended use.

- Establish a Strong Data Governance Framework: Create clear policies and Standard Operating Procedures (SOPs) for system use, data entry, audit trail review, security, and archiving. Train all personnel regularly and enforce these policies consistently.

- Prioritize Secure Archiving and Data Retrieval: Electronic records must be retained for decades. Implement a compliant, secure, and searchable archiving solution that protects data from alteration and ensures it can be retrieved in a readable format throughout its entire retention period, even as technology evolves.

- Conduct Regular Internal Audits and Training: Proactive internal audits help identify and rectify compliance gaps before an FDA inspection. Continuous training ensures that staff remain aware of their responsibilities and the importance of data integrity.

- Choose Vendors with Proven Expertise: When selecting software or services, prioritize vendors with a deep understanding of Part 11 and GxP requirements. Their expertise can significantly reduce your implementation risk and time-to-compliance.

How Solix Helps Achieve and Maintain FDA 21 CFR Part 11 and GxP Compliance

Navigating the complexities of 21 CFR Part 11 and GxP can be a daunting, resource-intensive task. Many organizations find themselves juggling disparate systems, struggling with legacy data, and constantly preparing for the next audit. This is where Solix Technologies, as a leader in enterprise data management, provides a critical advantage. Solix offers a structured, proven approach to not only achieve compliance but to transform it from a cost center into a strategic asset.

Solix demonstrates its leadership through a deep, practical understanding of regulatory data lifecycle management. Our solutions are built on the foundation of the ALCOA+ principles, ensuring that data integrity is embedded into the very fabric of your information architecture. We don’t just provide software; we provide a framework for compliance that is trusted by organizations in highly regulated industries worldwide.

Here’s how the Solix approach directly addresses the core requirements of 21 CFR Part 11 and GxP:

- Ensuring System Validation and Control: The Solix Common Data Platform (CDP) is designed with compliance in mind. Our solutions facilitate the validation process with well-documented architecture and functionalities, helping you meet the stringent requirements for proving system accuracy, reliability, and consistent intended performance.

- Implementing Immutable Audit Trails: Solix technologies enforce robust, automated audit trails. Every action on a record is automatically logged, capturing the who, what, when, and why of any change. These audit trails are securely stored and easily accessible for review, making internal and regulatory audits a streamlined process.

- Managing Secure Archiving and Long-Term Retention: This is a core strength of Solix. We provide a secure, compliant archive for electronic records, ensuring they are protected from alteration or deletion while remaining fully accessible. We solve the challenge of long-term data retention, ensuring records remain readable and usable for their entire mandated lifecycle, mitigating the risks associated with data obsolescence.

- Enforcing Rigorous Access Controls: The Solix platform includes sophisticated security features that allow you to define and manage user access with precision. You can ensure that individuals only have access to the data and functions necessary for their job role, a fundamental requirement for protecting electronic records.

- Supporting a Compliant Data Lifecycle: From creation and active use to archival and final destruction, Solix helps you manage the entire data lifecycle according to predefined, compliant policies. This includes managing records from legacy systems, bringing them into a unified, compliant archive, and reducing the cost and risk associated with maintaining outdated applications.

- Simplifying the Audit and Inspection Process: With all relevant GxP data consolidated, classified, and managed within a compliant framework, responding to regulatory inquiries becomes significantly faster and less stressful. Solix helps you quickly locate and produce the required records and audit trails, demonstrating control and transparency to inspectors.

By partnering with Solix, you move beyond simply checking compliance boxes. You empower your organization with a unified data management strategy that reduces risk, lowers the total cost of ownership, and builds a foundation of quality and trust. Let Solix handle the complexities of data compliance, so you can focus on your core mission: developing life-changing products.

Frequently Asked Questions (FAQs) about FDA 21 CFR Part 11 and GxP Compliance

What does 21 CFR Part 11 apply to?

21 CFR Part 11 applies to any electronic records and electronic signatures that are created, modified, maintained, archived, retrieved, or transmitted under any FDA GxP regulations, including Good Manufacturing Practice (GMP), Good Clinical Practice (GCP), and Good Laboratory Practice (GLP).

What are the 5 principles of ALCOA in FDA?

The five core principles of ALCOA are: Attributable (who created the data), Legible (can the data be read), Contemporaneous (was it recorded at the time of the activity), Original (is it the source record), and Accurate (is the data correct). The extended principles, ALCOA+, also include Complete, Consistent, Enduring, and Available.

What is the difference between GxP and 21 CFR Part 11?

GxP refers to the broad set of quality regulations (like GMP, GLP) that mandate what must be documented. 21 CFR Part 11 is the specific rule that defines how those documentation requirements can be met using electronic records and signatures instead of paper.

Is 21 CFR Part 11 a legal requirement?

Yes, 21 CFR Part 11 is a legally enforceable regulation issued by the U.S. FDA. Failure to comply can result in significant regulatory actions, including warning letters, product seizures, and injunctions.

What is an example of a 21 CFR Part 11 compliant system?

A compliant system, such as an Electronic Document Management System (EDMS) or a Laboratory Information Management System (LIMS), would feature validated processes, secure user access with unique logins, automated and immutable audit trails, and electronic signatures that are uniquely linked to an individual.

What are the key components of an electronic signature under Part 11?

An electronic signature under Part 11 must be unique to one individual and cannot be reassigned. It must also employ at least two distinct identification components, such as an ID/password plus a security token or biometric data, to verify the signer’s identity.

How long must electronic records be retained under GxP?

Retention periods are typically defined by the underlying GxP regulation. For many products, this can be for the lifetime of the product plus several years, often spanning decades. The key is that records must be available and readable for the entire duration.

What is the best way to prepare for an FDA Part 11 inspection?

The best preparation is to have a well-documented and consistently followed quality system. This includes having validated systems, up-to-date SOPs, completed training records, and the ability to quickly generate and present specific electronic records with their full audit trails upon request.